Technoeconomic & Life-Cycle Analysis

About Our Work

We apply Life Cycle Assessment (LCA) and Technoeconomic Analysis (TEA) to a wide variety of established and emerging energy technologies and strategies. LCA is a method that can be used to evaluate the potential environmental impacts of a product, material, process, or activity. TEA refers to cost assessments, including cost of production (minimum selling price at facility gate) and life-cycle cost (total cost of ownership, which may include monetized externalities) that require deep technical knowledge and a combination of engineering design and more traditional cash flow analyses.

Technoeconomic and life cycle analysis —in conjunction with other forms of decision analysis—help guide technology development and improvement targets, inform comparative pathway decisions, evaluate policy feasibility, and provide policy guidance through early identification and mitigation of financial or technical challenges.

Emerging Technology Assessment

We participate in collaborative projects with experts from the Department of Energy, National Labs, and U.S. and international universities to develop methods and guidelines for applying LCA and TEA techniques and concepts to low-TRL (emerging) technologies in order to: accelerate technology maturation; improve performance, costs, and minimize environmental impacts; and minimize unforeseen risks.

Bioeconomy and Biomanufacturing

Process simulation and carbon accounting for biofuels and bioproducts

Bio-based fuels and chemicals, combined with sustainable agricultural and forestry practices, are key to enable a full transition away from petroleum. The team in ETA leads technoeconomic analysis and life-cycle assessment research in this area as part of the Joint BioEnergy Institute and has deployed public-facing webtools for evaluating a variety of bio-based production processes.

Circular Manufacturing and Materials

Finding bottlenecks and opportunities on the path to a circular economy

The transition toward a circular economy will require novel materials, advanced recycling processes, and a massive infrastructure build-out. The team has worked closely with basic scientists and stakeholders in the waste management industry to evaluate infinitely recyclable plastics and carbon fiber upcycling, and highlight key infrastructure gaps that must be filled to enable a clean, equitable transition to a zero-waste future.

Critical Materials and E-Waste Recycling

Analysis to build strategies around metal supply chains

Profitable and sustainable pathways for handling waste from the energy sector and for sourcing critical materials must be identified to meet growing demand. The ETA team uses a combination of geospatial analysis and material flow analysis to identify opportunities for new regional material supply chains, as well as technoeconomic analysis to verify the potential of developing new sources for lithium and for lowering the impact of existing mines.

Hydrogen and Fuel Cell Technologies

Process simulation and analysis to focus basic and fundamental research

New technologies for hydrogen production, storage, and use are necessary for scaling green hydrogen in hard to decarbonize sectors. The team in ETA leads high-throughput material screening, process design and simulation, and technoeconomic and environmental impact analysis, and leads the system analysis task for the DOE HyMARC program.

Long-Duration Energy Storage

Developing performance targets for 10+ hour energy storage

Increasing the use of variable renewable energy requires developing low-cost long-duration energy storage. The ETA team is using reverse engineering to benchmark scientific innovations for thermal energy storage and hydrogen storage from the technical requirements of a target application.

Methane Emissions Monitoring and Reduction

Geospatial analysis to develop cost curves for methane mitigation

New geospatial approaches and detection technologies are emerging that could greatly reduce the cost of monitoring regions for methane leaks. The ETA team is working alongside EESA teams to apply these advances to develop low cost strategies for methane mitigation.

Negative Emissions Technologies

Lowering barriers to deployment and developing methods for validation

Negative emissions technologies such as direct air capture and enhanced weathering are critical for lowering the concentration of CO2 in this century to sustainable levels. The ETA team is developing and applying rigorous and reproducible methods for verifying cost, benefits and net CO2 reduction to clarify the state of technology and identify opportunities for overcoming deployment challenges, including the transport, storage, and use of captured CO2 or carbon. This work is part of the Carbon Negative Initiative.

Waste-to-Energy Systems

Diverting waste to produce electricity, heat, liquid fuels, and products

Using organic waste for the production of value-added energy carriers and other products can reduce our reliance on landfilling and reduce emissions of potent greenhouse gases such as methane. ETA scientists measure and model the emissions and economic implications of more sustainable waste management practices, including anaerobic digestion and composting.

Water-Energy Nexus

Rigorous analysis to reach pipe parity

New technologies for utilizing and recycling unconventional water sources and for more efficiently managing wastewater are essential to supply communities, farms, and industrial facilities across the U.S. and the world with adequate clean water. The team in ETA has deep expertise in TEA and LCA of water infrastructure systems and plays a leading role in the data, modeling, and analysis pillar of the National Alliance for Water Innovation.

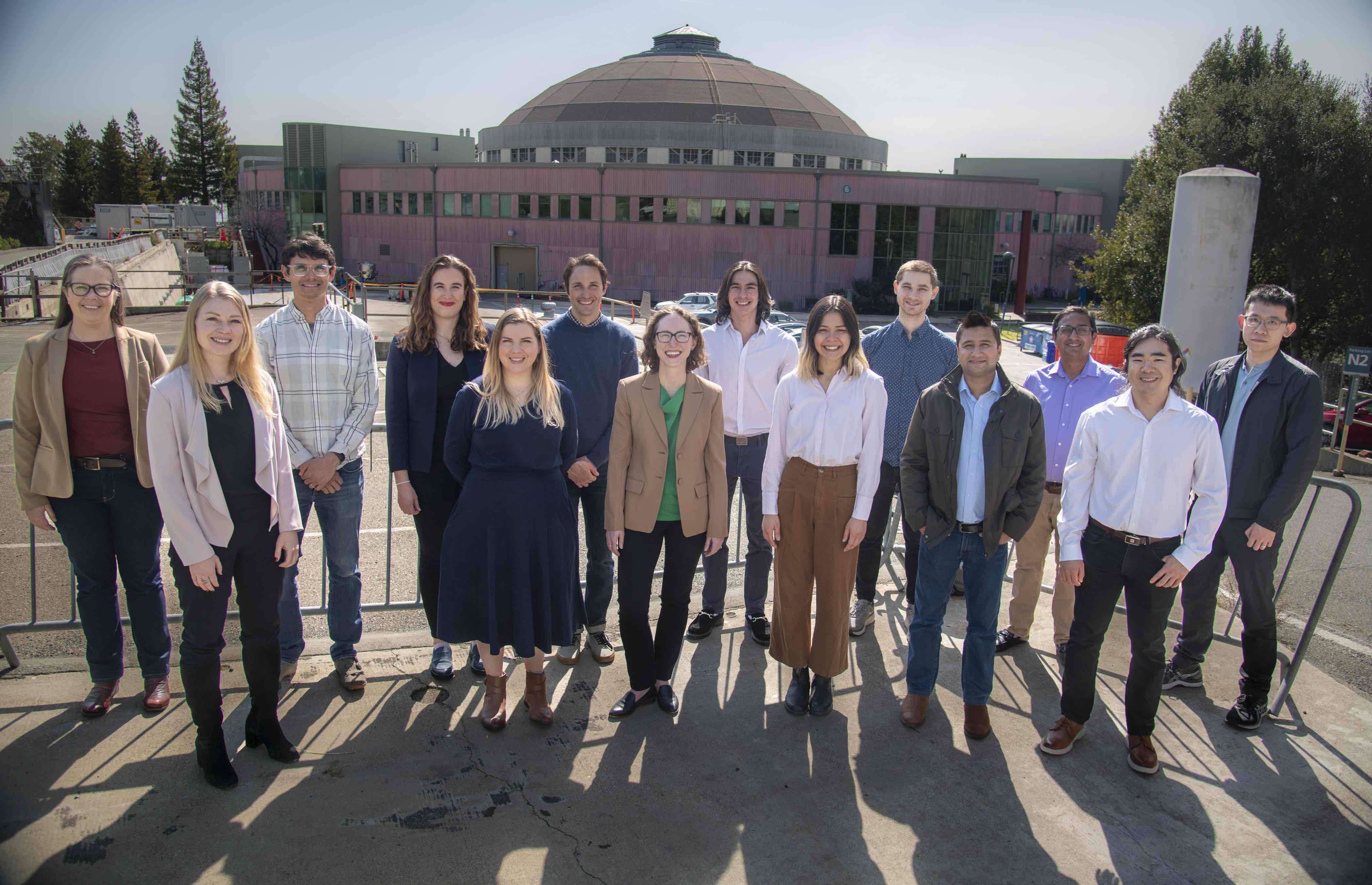

Energy Technologies Area Team Members

Additional Team Members

Nawa Baral

Nawa Baral

Project Scientist, BioSciences Area

Tyler Huntington

Tyler Huntington

Software Developer, Joint BioEnergy Insititute

Baishakhi Bose

Baishakhi Bose

Postdoc, Biosciences Area

Tao Dai

Tao Dai

Postdoc, Biosciences Area

Melissa Moore

Melissa Moore

Postdoc, Biosciences Area